Table of Contents

As electronics become increasingly compact and complex, the demand for innovative circuit board technologies continues to grow. Among these technologies, rigid-flex PCBs stand out for their unique ability to combine the strengths of rigid and flexible circuit boards into a single, versatile solution. From smartphones and medical implants to aerospace and industrial devices, rigid-flex technology is transforming the way engineers design high-performance electronics.

This guide explores key insights into rigid-flex PCB applications and materials, while also highlighting the role of leading PCB manufacturers and suppliers in the world that support this growing industry.

What Is a Rigid-Flex PCB?

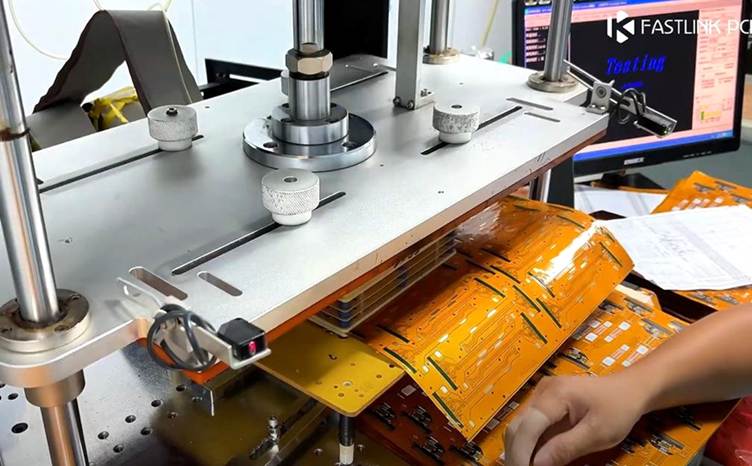

A rigid-flex PCB is a hybrid printed circuit board that merges rigid substrates with flexible layers. These flexible sections allow the board to bend or fold during installation, while the rigid areas support component mounting and structural stability. The flexible layers are often laminated between or connected to the rigid sections, creating a durable and space-efficient circuit solution.

Common Materials Used in Rigid-Flex PCBs

The performance and reliability of a rigid-flex PCB depend heavily on its materials. Some of the most widely used materials include:

1. Polyimide (PI) Film

Polyimide is the most common substrate for the flexible portion of the board. It provides excellent flexibility, thermal resistance, and chemical stability, making it ideal for demanding applications.

2. FR4 Laminate

The rigid portions are typically constructed using FR4, a flame-retardant epoxy laminate known for its mechanical strength and electrical insulation properties.

3. Adhesives and Coverlays

High-performance adhesives are used to bond layers together. Coverlays—usually made from polyimide film—are added to protect the flexible circuits from environmental damage.

4. Copper Foil

The conductive traces are formed from rolled annealed (RA) or electro-deposited (ED) copper. RA copper is more suitable for dynamic flexing applications due to its higher ductility.

Rigid-Flex PCB Applications Across Industries

The adaptability of rigid-flex PCBs makes them suitable for a wide range of modern electronic applications where space, durability, and performance are critical.

1. Consumer Electronics

Rigid-flex PCBs are frequently used in smartphones, cameras, laptops, and wearable devices. Their ability to fit into tight spaces and accommodate complex geometries makes them ideal for sleek, compact product designs.

2. Medical Devices

In the medical field, these boards are found in diagnostic equipment, implantable devices, hearing aids, and handheld monitors. The flexibility and reliability of rigid-flex PCBs help ensure consistent performance in critical healthcare applications.

3. Aerospace and Defense

With strict performance standards and limited installation space, aerospace and military applications rely on rigid-flex PCBs for avionics, satellites, radar systems, and communication equipment. The boards’ resistance to vibration, heat, and mechanical stress makes them well-suited for harsh environments.

4. Automotive Electronics

Modern vehicles are packed with electronic features—such as ADAS, infotainment, lighting systems, and sensors—that demand reliable, space-efficient PCBs. Rigid-flex solutions offer both high durability and design flexibility for automotive engineers.

5. Industrial and Robotics

In factories and industrial settings, rigid-flex PCBs are used in automation systems, sensors, control panels, and robotic arms. Their ability to withstand continuous motion and high mechanical stress ensures longer product life cycles.

Benefits of Rigid-Flex PCBs

- Space and weight reduction: Fewer connectors and cables are needed, which leads to more compact, lightweight designs.

- Improved reliability: Fewer solder joints and connectors mean less chance of failure.

- Simplified assembly: One integrated board instead of multiple interconnected PCBs.

- Better performance in motion: Ideal for dynamic flexing and high-vibration environments.

- Enhanced signal integrity: Shorter interconnect paths reduce signal loss and EMI issues.

Leading PCB Manufacturers and Suppliers in the World

The production of rigid-flex PCBs requires advanced engineering, precision fabrication, and quality assurance. Here’s a brief overview of the types of PCB manufacturers and suppliers in the world that are driving innovation in this space.

1. Asia-Pacific Manufacturers

Countries like China, Taiwan, South Korea, and Japan dominate the global PCB manufacturing sector. They offer cost-effective, high-volume production and are home to many large-scale manufacturers with strong capabilities in rigid-flex PCB fabrication.

2. North American Suppliers

The USA and Canada are known for high-reliability PCB manufacturing, particularly in aerospace, medical, and defense sectors. Manufacturers in this region often focus on quality certifications, fast prototyping, and low-to-medium volume production.

3. European Producers

Germany, the UK, and other EU nations emphasize precision engineering and environmental compliance. European PCB suppliers are known for their high standards in automotive and industrial PCBs.

4. Global Turnkey Service Providers

Some international companies offer end-to-end solutions including design, prototyping, assembly, and testing. These suppliers are especially useful for startups and businesses that prefer to outsource the entire product development cycle.

When selecting a rigid-flex PCB supplier, consider their specialization, certification standards (like ISO and IPC), production capabilities, and support for prototyping and volume scaling.

Also Read: Leading E-commerce Solution: a Roadmap to Online Success

Conclusion

Understanding rigid-flex PCB applications and materials is essential for engineers and product developers looking to design compact, high-reliability electronics. These hybrid circuit boards offer the best of both worlds: the structural integrity of rigid boards and the adaptability of flexible circuits.

As demand for smart devices, medical innovations, and connected vehicles continues to grow, rigid-flex PCBs will play a key role in powering the technology of tomorrow. Whether you’re launching a new consumer gadget or building mission-critical aerospace systems, choosing the right PCB manufacturers and suppliers in the world is crucial to ensuring quality, performance, and long-term success.

If you’re considering rigid-flex PCBs for your next project, look for experienced partners who can provide engineering support, material guidance, and precision manufacturing tailored to your needs.